Exo Gas — Hermetic Glass-to-Metal Sealing Solutions

Roselle Park, New Jersey / USA

For Aerospace, Defense, Oil + Gas Exploration, Medical

Introduction

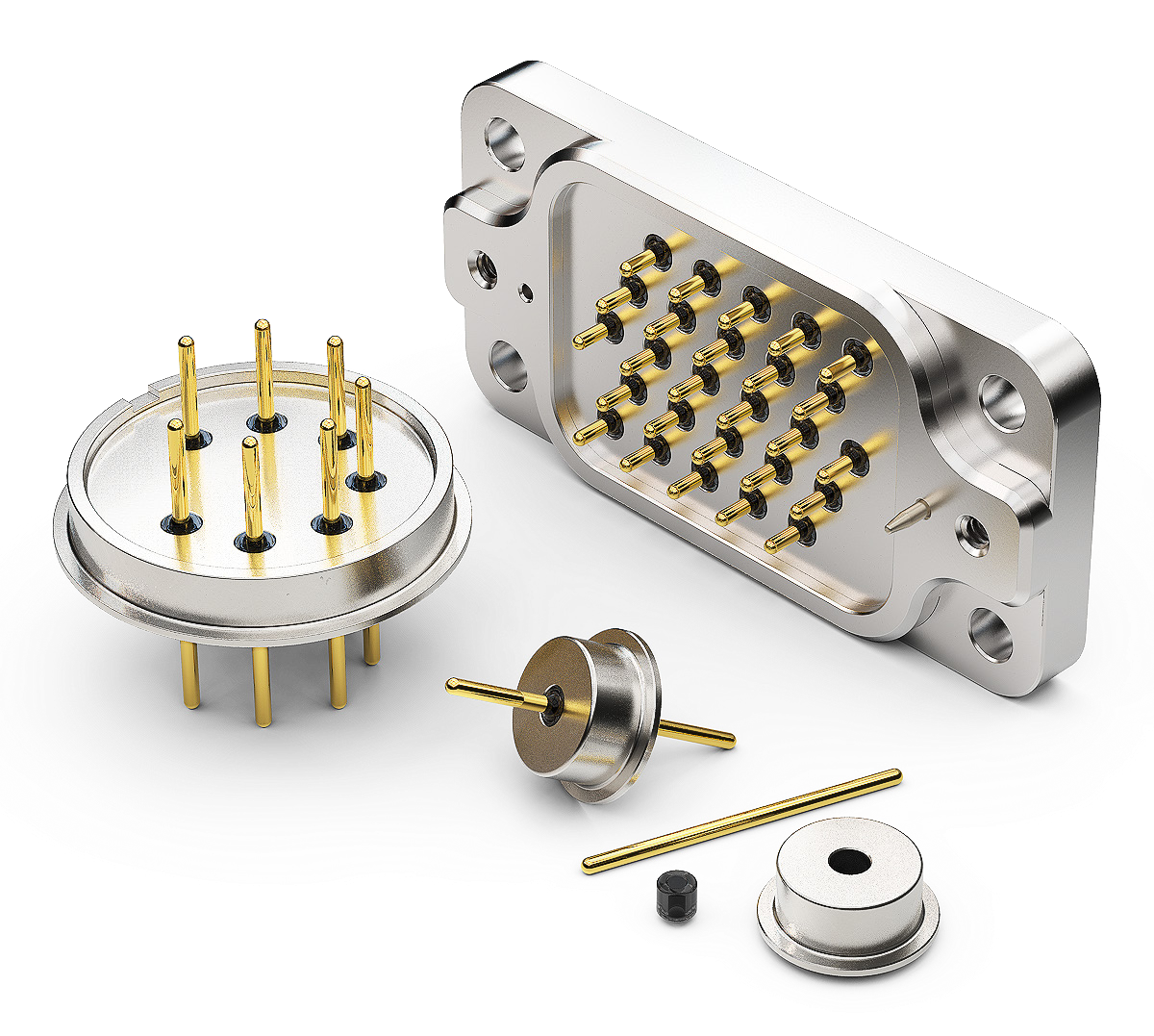

Glass to Metal Seal Manufacturer

Hermetic Systems is a glass to metal seal manufacturer to meet your unique hermetic requirements. Located in Roselle Park, New Jersey, Hermetic Systems manufactures hermetic feedthroughs for various global fields including Aerospace, Automotive, Electronic, Medical for industrial and researched based uses.

Process

Hermetic Systems utilizes various atmospheres in our sealing ovens. We are capable of working with a variety of steels including Stainless Steel, 52 Alloy, Kovar, and cold-rolled steel. Our team is ready to handle projects from one-off sampling to large volume production lines. Hermetic Systems is committed to adhering to a process-based approach in order to meet a variety of customer needs. Our team represents 50+ years in combined experience in glass and glass to metal sealing. We are also proud to provide a number of metal finishing and plating options.

Process Steps

- • Glass Expertise

- • Machining

- • Material Prep

- • Sealing

- • Cleaning and Passivation

- • Metal Finishing

Sealing Metals

- • Stainless Steel

- • 52 Alloy

- • Kovar

- • Cold-Rolled Steel

Glass Types

- • 7056

- • 7052

- • 9013

- • 9010

- • TA23

- • Custom Glasses

Contact

Get In Touch

Contact us for your hermetic glass-to-metal sealing needs.

Hermetic Systems, LLC

135 West Clay Avenue

Roselle Park, NJ 07204

Telephone: 1-908-620-3300

Facsimile: 1-908-123-4567